Tube filler for matel tube RTMF-60

Main features and technical parameters:

- Transmission of the closure on the platform below, safe, reliable,

pollution-free.

- filling and sealing part of the installation of the platform no more than semi-closed within the static frame visual cover, easy to observe, easy

operation, easy maintenance.

- PLC + touch screen control, color graphics interface, man-machine dialogue.

- Adjustable speed control positions accompanied by (also adjustable swing angle) the entire series manipulator, control devices and vacuum generators to supply accurate and stable hose).

- handrails in a vacuum on the tube under the action of turning about 90 o, the hose is pressed into the elastic tube station on the tube cup.

- Photoelectric on standard workstations with high-precision color detector,stepper motor control patterns in the correct position hose.

- filling nozzle according to the characteristics and quantity of filling material to determine its size, can provide the form of a blow off nozzle type, style and blow off all of comprehension.

- No tube no filling.

- Sealing much more flexible manipulator can be adjusted through different to achieve the end of the second fold, three fold and saddle-shaped tail end off.

- type code code print workstation automatically requests the position in the process.

- Fault alarm, overload shutdown

- count and quantitative down

- Suitable for: Metal Pipe

- production capacity :30-60 / min

- Filling capacity :2-80ml / support

- Filling error: ≤ ± 1%

- for hose diameter: 10-28 mm

- For hose length :50-160 mm (length Lid)

- Main motor power: 1.1kw

- Working pressure :0.5-0 .6 MPa

- Displacement: not more than 600L/min

- Overall dimensions: 1950 × 750 × 1850mm

- Weight: 900 kg

- Standard: saddle-shaped folded sealing device can achieve by adjusting the

folding and fold sides of the trilateral

- Standard: Xiegua automatic feeding tube position matching the entire series:

Laminated Barrel insulation device

- Optional: internal agitator barrel selection: automatic feeding device (pump)

- Optional: pipe finished products output transmission device

Products

Our product category

Company information

- Richmech Industrial Co.,Ltd.

- TEL : 886-2-2502-2949

- FAX : 886-2-2505-0192

- Contact Person : Allen Chen

- richmechids@yahoo.com.tw

Sitemap

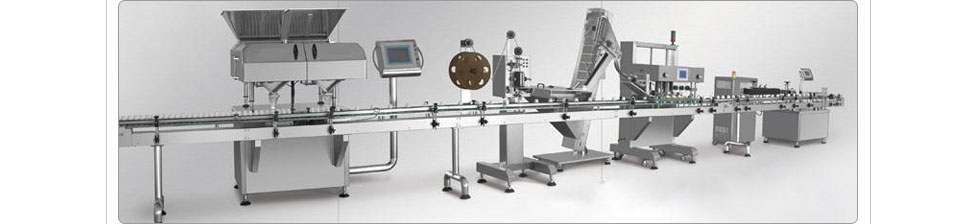

Automatic Tablet Counting Line Automatic Liquid Filling Capping Line