Tube filler for plastic tube RTPF-60

Main features and technical parameters:

- Transmission of the closure of the platform below, safe, pollution-free

- filling and sealing part of the installation of the platform no more than semi-closed within the static frame visual cover, easy to observe, easy

operation, easy maintenance

- PLC touch screen control, color graphics human-machine interface dialogue

- Adjustable speed control positions accompanied by (also adjustable swing angle) the entire series manipulator, control devices and vacuum generators to supply accurate and stable hose

- handrails in a vacuum on the tube under the action of turning about 90 o, the hose is pressed into the elastic tube station on the tube cup

- Photoelectric on standard workstations with high-precision color detector,stepper motor control patterns in the correct position hose

- filling nozzle according to the characteristics and quantity of filling material to determine its size, can provide the form of a blow off nozzle type, style and blow off all of comprehension

- No tube no filling

- Sealing generator tubes with hot air heating and external wall close to the end of the outer wall of the hose to cool the cooling water jacket, to ensure that the internal tail tube seal tight, the text looks clear and beautiful

- pressure synthetic station printing code, robot automatic pressure seal at the same time code printed on the technological requirements of the position

- Cut plastic hose robot cut the Department of straight or shaped into a tail

- stop counting and quantitative

- production capacity :30-80 / min

- Filling Capacity :5-400ml / support

- Filling error: ≤ ± 1%

- for hose diameter: 10-50 mm

- Main motor power: 1.1kw

- For hose length :50-200 mm (length Lid)

- Working pressure :0.5-0 .6 MPa

- Displacement: not more than 600L/min

- Weight: 1200 kg

- Overall dimensions: 1950 × 750 × 1850

Products

Our product category

Company information

- Richmech Industrial Co.,Ltd.

- TEL : 886-2-2502-2949

- FAX : 886-2-2505-0192

- Contact Person : Allen Chen

- richmechids@yahoo.com.tw

Sitemap

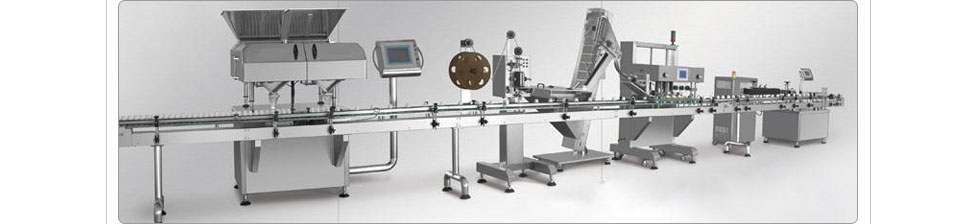

Automatic Tablet Counting Line Automatic Liquid Filling Capping Line